From July 8 to 11, 2024, the 2nd SIEGENIA Technology Camp took place at the SIEGENIA GRUPPE in Wilnsdorf-Niederdielfen. 8 pupils from Niederdielfen secondary school worked with trainees from the SIEGENIA GROUP, Team Fab Lab from the University of Siegen and FRids e.V. built and 3D-printed marble runs. The low-threshold activity was designed to get children interested in STEM subjects and introduce them to technical professions.

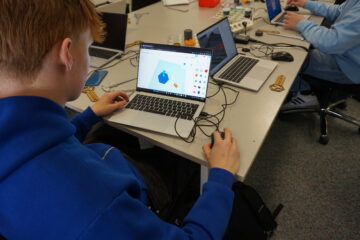

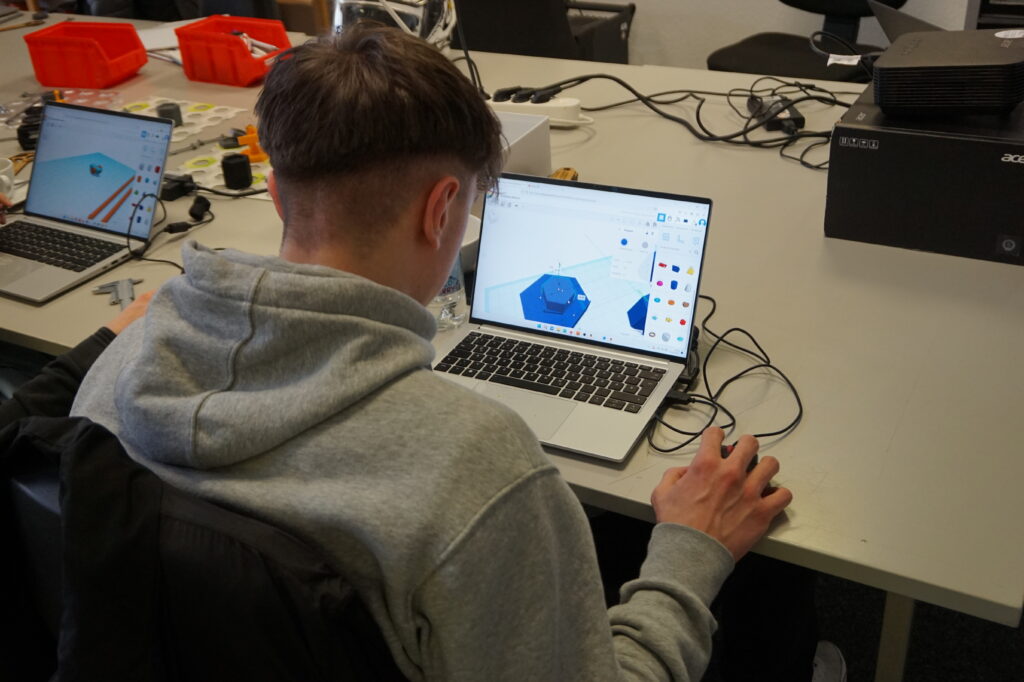

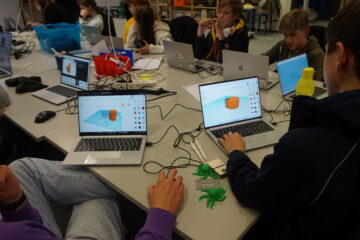

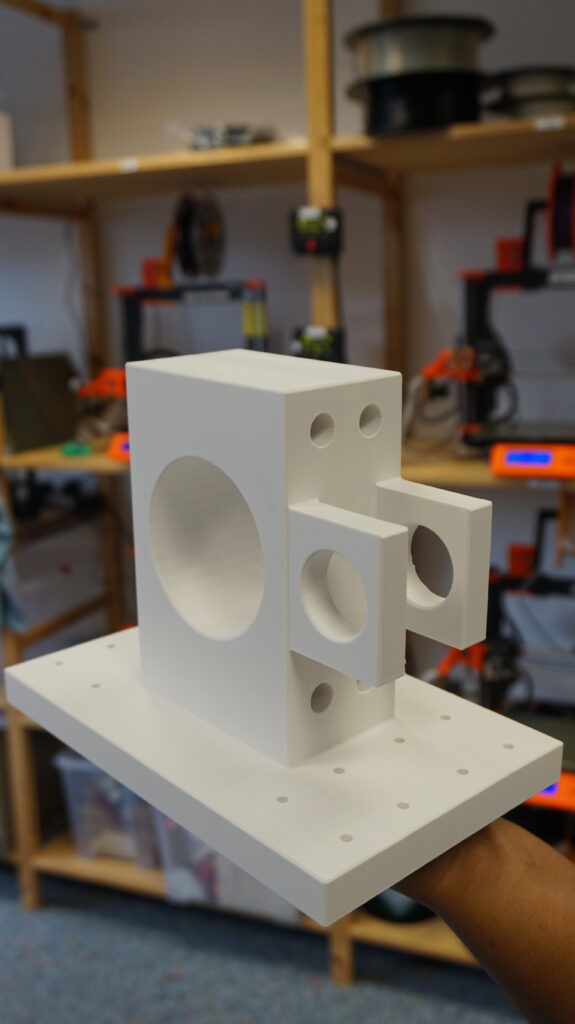

Elon Musk’s laptops, 3D printers and satellite internet were brought from the Fab Lab in Siegen to the training center to provide the necessary infrastructure. This concept proved to be very successful at the 1st SIEGENIA Technology Camp during the Easter vacations. Over four days, the children were taken from 0 to 100 – they became experts in topics relating to additive manufacturing, reverse engineering and design. The whole thing revolved around the construction of marble runs – what to do if parts of the run are suddenly missing? Measurements had to be taken with calipers – accurate to two decimal places. The measurements were then recorded on paper sketches. In the final step, the sketches were converted into digital drawings and printed out using the 3D printer.

FRids e.V. once again provided support with its many years of experience in youth work. Four energetic trainees from the SIEGENIA GROUP looked after the children and provided guidance at the training center. Machines such as the band saw in particular need to be looked after, because it’s not just about 3D printing. The entire training center could be used to solve the tasks. As part of the “EnvironMINT” project funded by the Federal Ministry of Education and Research, the Fab Lab team at the University of Siegen investigated the conditions for the success of good STEM education. “We want to enable cool STEM formats in the region that provide low-threshold access to technical topics and at least do not obviously have to do with “learning”. “Kids are already learning enough at school,” says Marios Mouratidis, Head of the Fab Lab at the University of Siegen. In this format, the partners placed great emphasis on self-determined, problem-solving and creative action on the part of the participants. While the basics were taught after just 1-2 days, the young people were then able to use the remaining time creatively and produce their own components for the marble runs.

On the last day of the technology camp, a closing event was held to which the parents of the participants were invited. Here, the young people had the opportunity to present their results.

The technology camp is organized in cooperation with Nina Herter and Sven Wiechmann from the SIEGENIA GROUP, Marios Mouratidis, head of the Fab Lab at the University of Siegen and Ulrike Monreal from FRids e.V.. The partners plan to continue promoting STEM in Siegen-Wittgenstein in the future.

On Thursday, July 11, the parents of the participants were invited to a presentation of the results.