Of course we want them: 6-core i5 CPUs, M.2 SSDs and 8 GB DDR4 Ram are a good basis for an office or gaming computer. As you know, we have been getting more and more involved in STEM education since last year. So this calls for a cool format where we can dismantle computers, assemble them back together and then give them to participants for free. Thus, we were happy to accept the offer.

But how do we transport 300 computers to the Fab Lab? That’s not only 1,800 CPU cores, 2,400 GB Ram and 150,000 GB memory in total, but also 2.1t total weight…

The Lions Club Siegen and the SIEGENIA GROUP were kind enough to help us. “We do not have a truck available, but we will rent one for you.”, said Wieland Frank, owner of SIGENIA GROUP. Two employees also came to support. Thanks again!

Now we are planning a new workshop series that (hopefully) launches in October:

“Build your own computer” (just a working title, suggestions are welcome).

The idea: young participants take apart computers with us, we look at the components and how they work and then reassemble them together. Afterwards an operating system will be installed and at the end the participants can take the computers home.

We can use your support:

- Helpers to support the workshop implementation,

- 300 mice, keyboards and/or monitors (could be used, but should be working and clean)

Schools are welcome to contact us. We heard that a few computer rooms here and there could be renewed.

We would like to do some research on the workshop as part of our EnvironMINT project to analyze the conditions for success of good STEM education in more detail. How can workshops be designed in an appealing way – especially to get young women and girls interested in STEM topics?

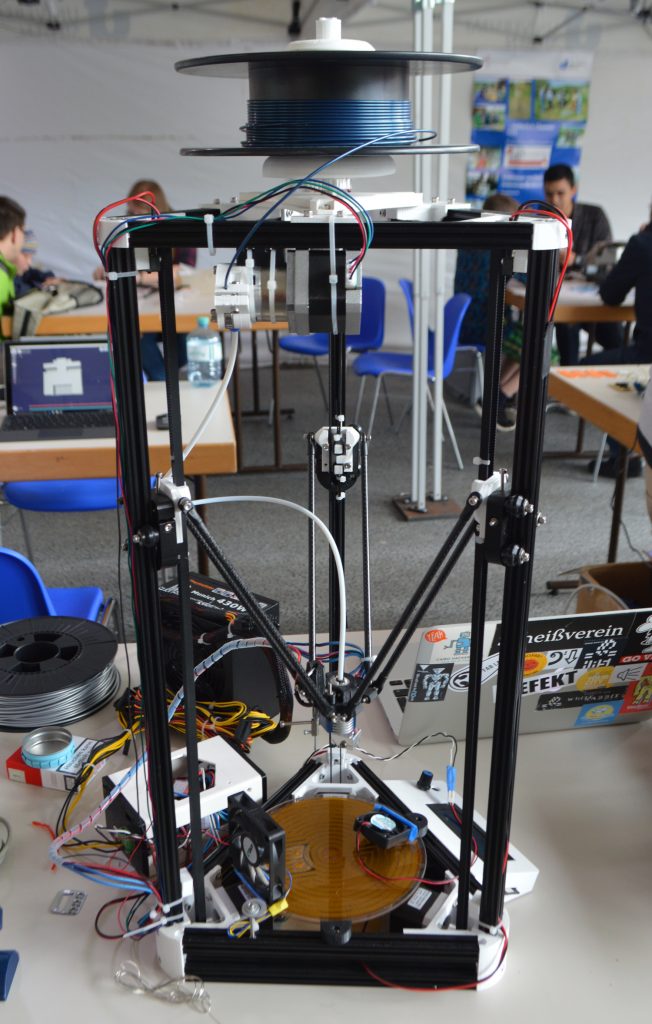

History lesson on STEM activities of the Fab Lab

With FAB:MAKE, we were able to purchase hardware that allows us to carry out workshops with smaller groups. As part of EnvironMINT, we are investigating the conditions for success of good STEM education with our partners (FAU Erlangen-Nuremberg, HS Rhein-Waal). In cooperation with Digitalum Bus, we are able to bring the topics mainly to the more rural areas in the old district of Wittgenstein.

From time to time, school classes also visit us and we carry out project days. But that’s not quite enough for us. We would like to build a strong network in Siegen-Wittgenstein with actors in the region: Schools, associations, companies, MINT partners and many more.

A lot of strong partners are already involved: Fab Lab Siegen, Digitalum-Wittgenstein gGmbH, FRids e.V., DRK Kreisverband Siegen Wittgenstein e.V., Bildungszentrum Wittgenstein, Lions Club Siegen, companies such as SIEGENIA GROUP and Pollrich GmbH, but also some schools as well as the Siegerlandmuseum.

We hope that the network will continue to grow and are excited about what we will achieve together in the future!