From the 25th to the 28th of March, a technology camp will take place at the SIEGENIA Ausbildungszentrum, which we are organising together with the SIEGENIA GROUP and FRids e.V.. The technology camp will give pupils from regional schools the opportunity to learn the basics of 3D-modelling and 3D-printing.

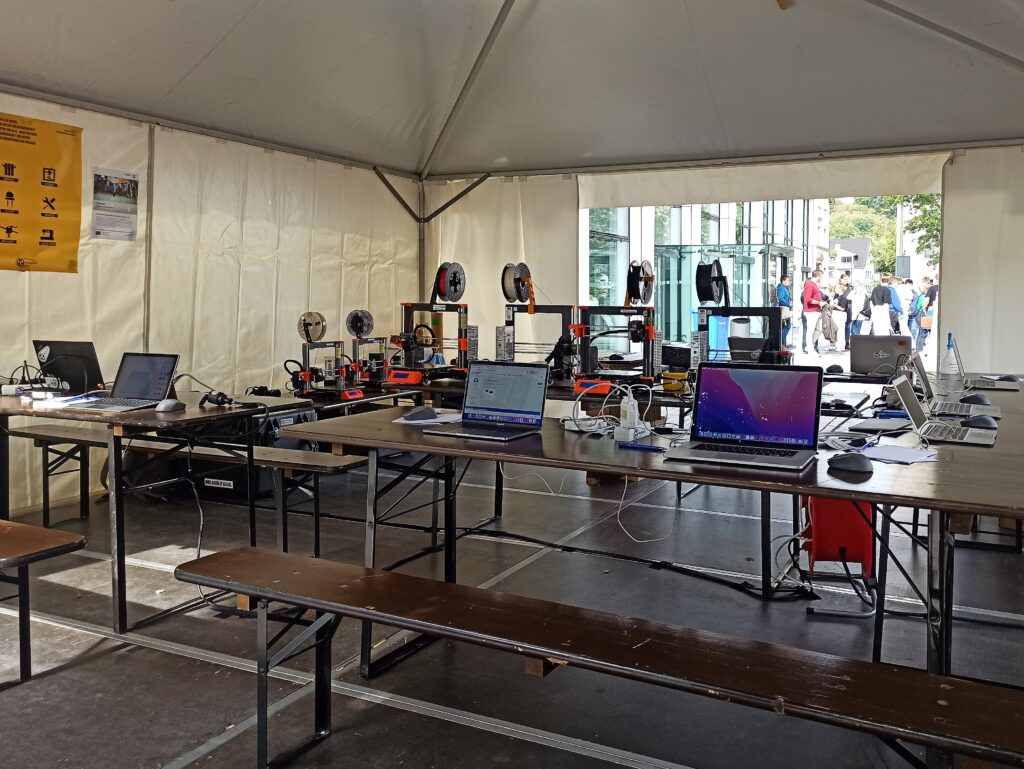

In order to provide the students with the best possible support, seven motivated trainees who work at SIEGENIA in the toolmaking and mechatronics departments were introduced to 3D printing in a train-the-trainer workshop here at the Fab Lab last week. Over the course of two days, our two colleagues, Marios Mouratidis and Jonas Kosiahn, taught the trainees how the technology works and how they can design and print their own models.

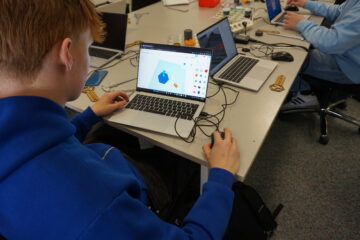

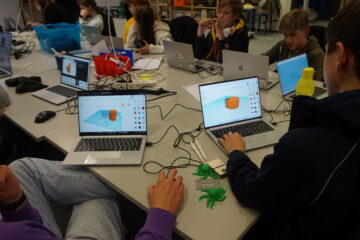

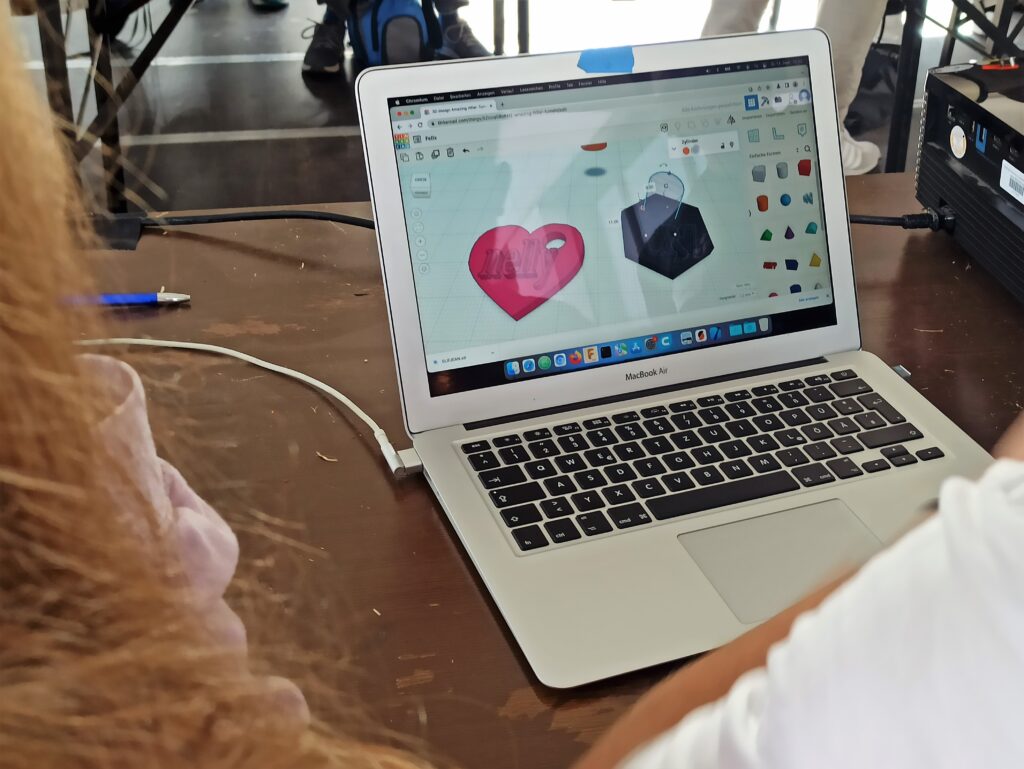

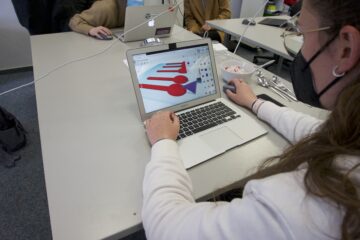

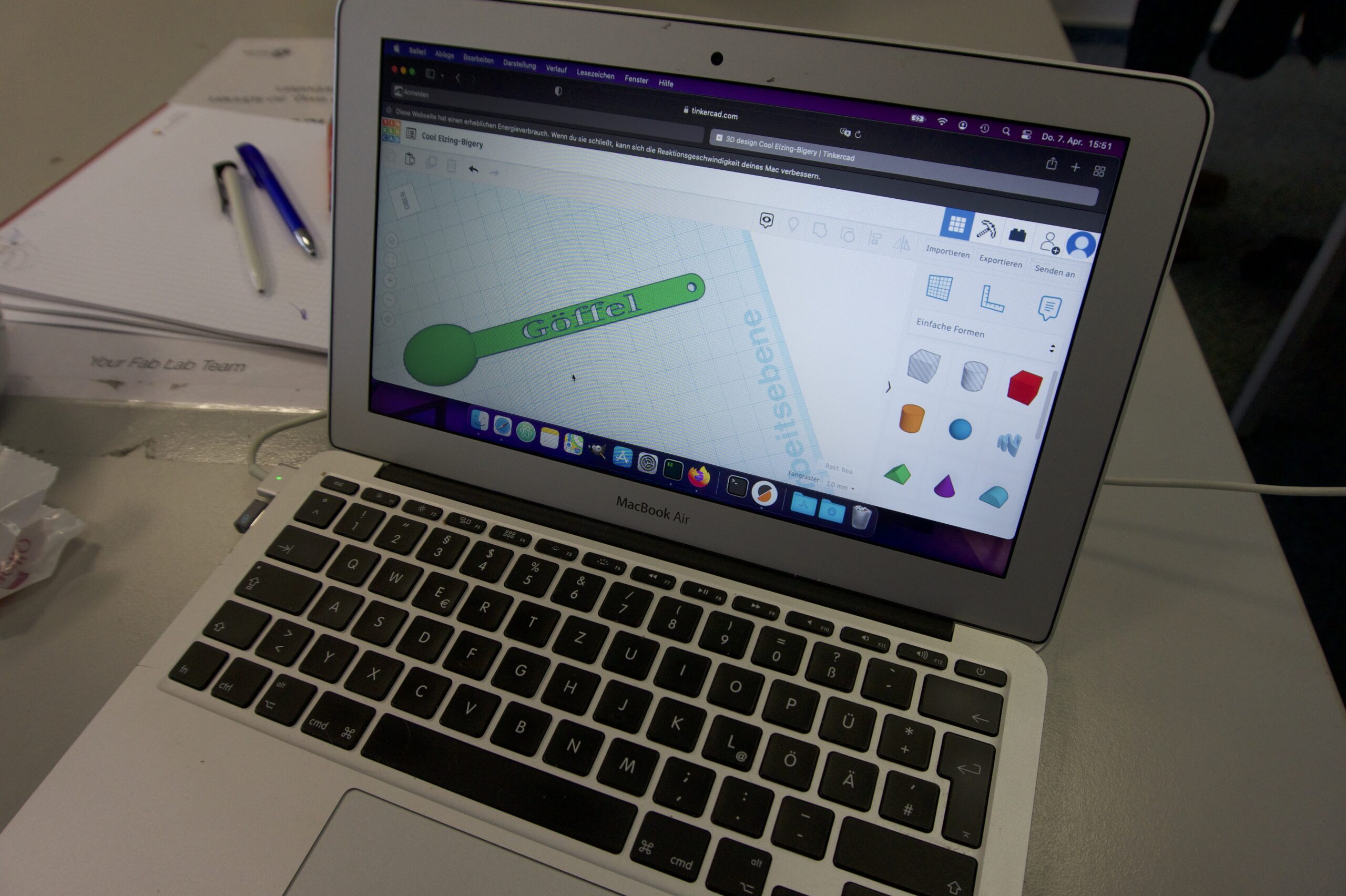

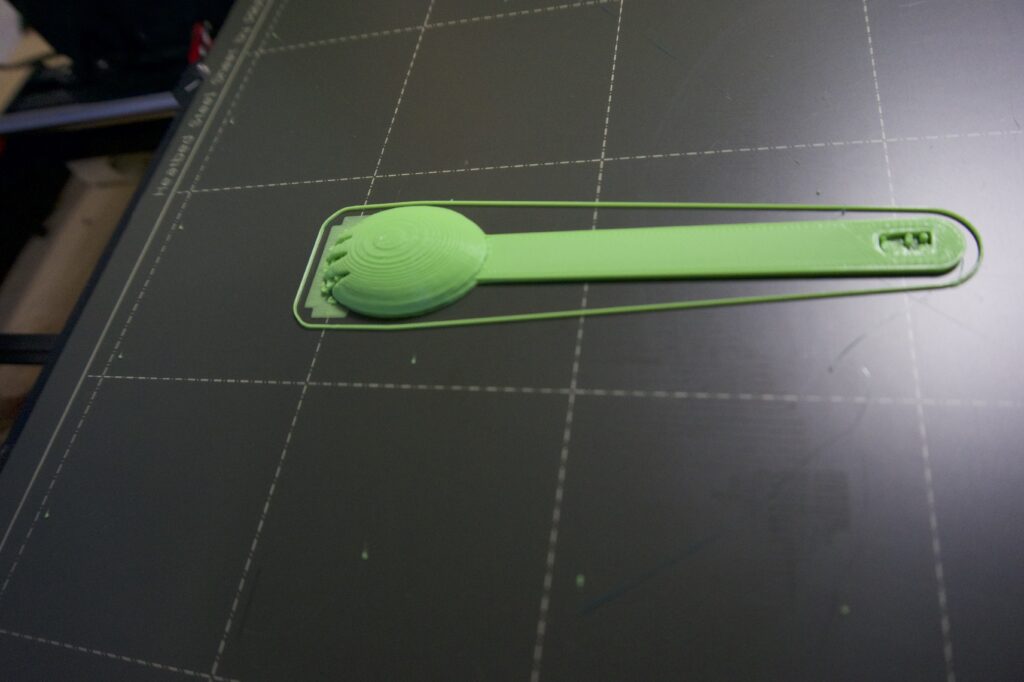

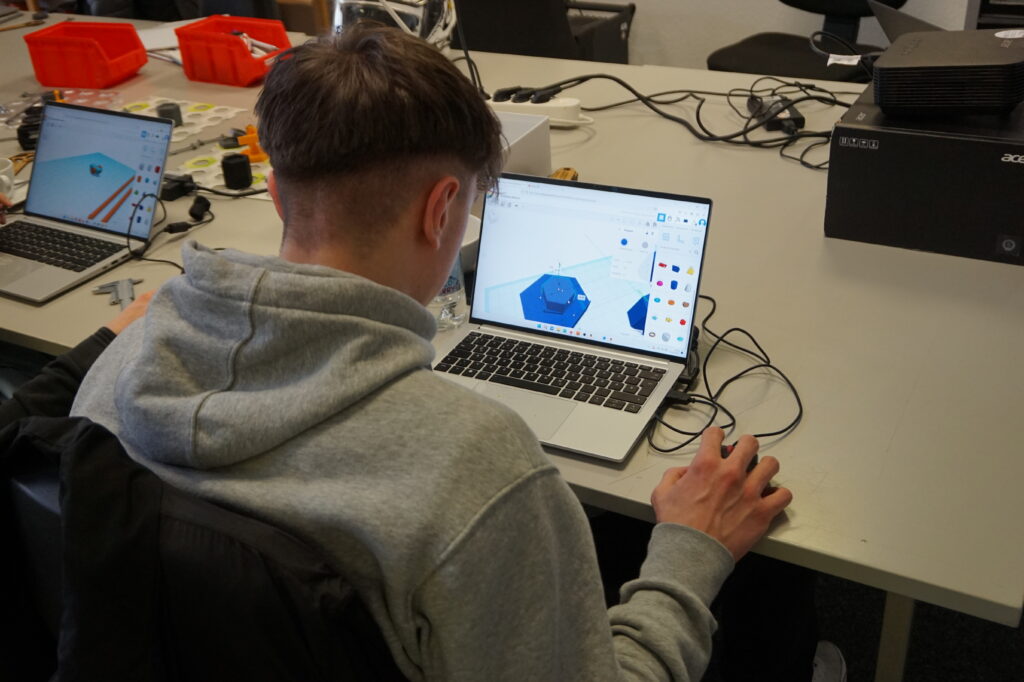

At the beginning of the workshop, the trainees were given an introduction to 3D printing and the modelling software TinkerCAD. Based on that, they were able to complete their first task: they independently modelled SIEGENIA key chains in TinkerCAD and then printed them.

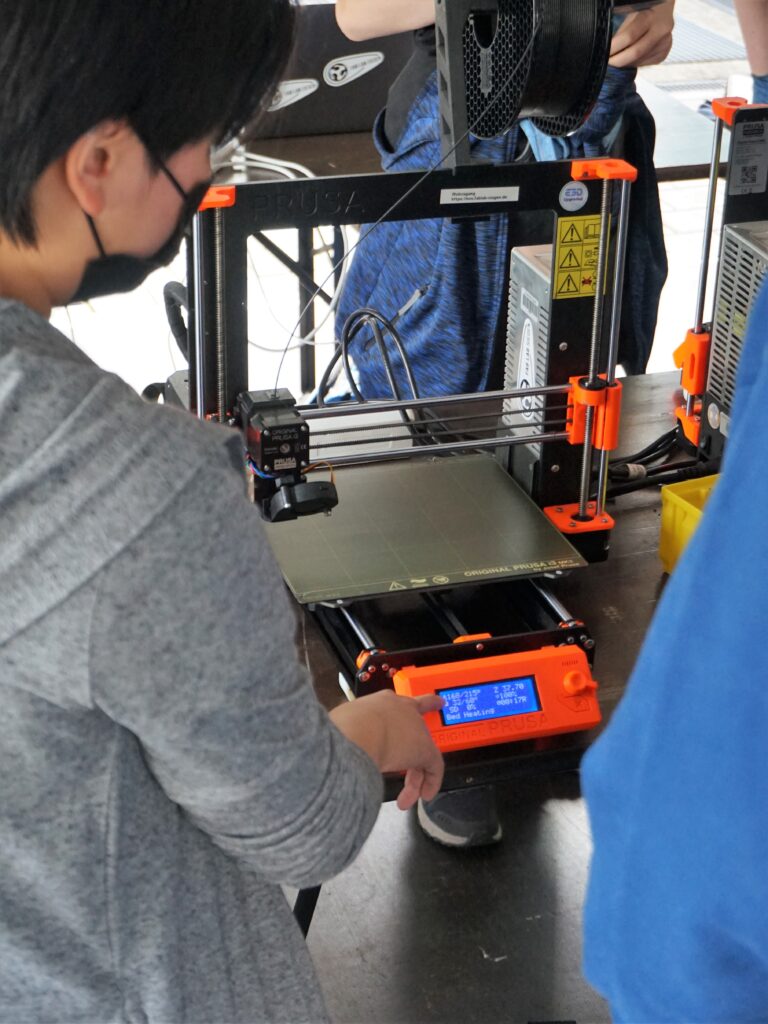

The trainees then worked with a ball track system and designed and printed spare parts. The trainees had the task of recreating individual parts of the ball track system in TinkerCAD and then printing them using our 3D printers. Thanks to the practical approach in the workshop, the trainees were able to apply the knowledge they had acquired directly and are now ready for the technology camp!

We are delighted to be able to support STEM education in the region with our collaboration partners, the SIEGENIA GROUP and FRids e.V.. We really enjoyed the workshop and look forward to seeing how the trainees pass on their newly learnt skills to the pupils at the upcoming technology camp!