Four students realized their planning and development project in the Fab Lab as part of their studies. This type of project is offered as a course as part of the Mechanical Engineering Program of Faculty IV at the University of Siegen. In this course, students work in groups on innovative technologies and concepts, which they present in a plenary session and document in a final report.

The goal of this project was to design a test rig for rubber bearing measurements in the chassis that can test all six degrees of freedom, since the current test rig of the Institute of Automotive Lightweight Design at the University of Siegen is not capable of doing so. The students focused on measuring U-bearings and RU-bearings.

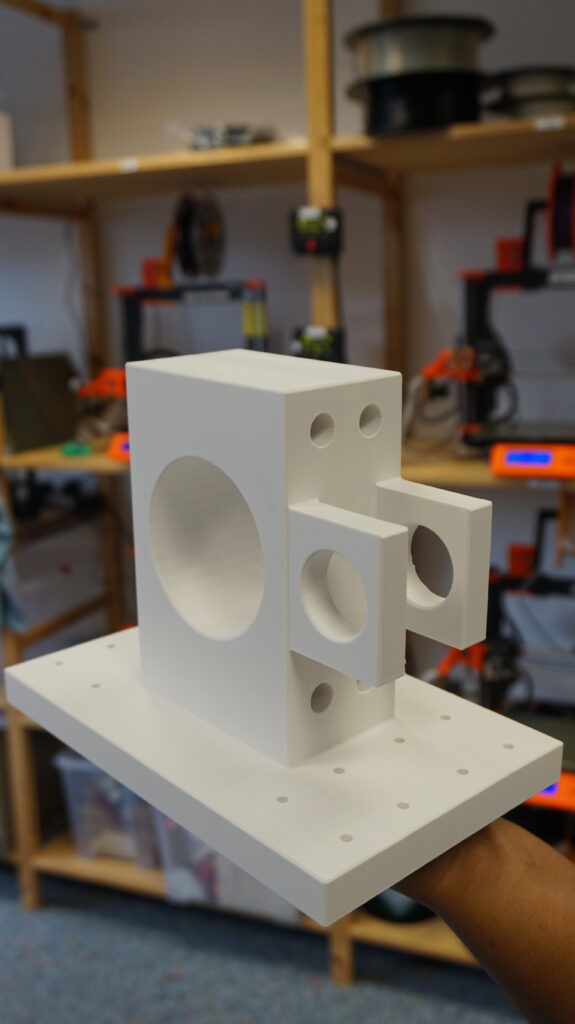

In order to be able to realize the concept they developed, they needed bearing supports that would hold the various bearings when subjected to the test forces. To do this, they developed a model for a U-bearing support and an RU-bearing support and then printed them three-dimensionally using one of our Prusa printers in the Fab Lab.

The respective bearings can be attached to the support with the help of four screws. In order to be able to screw the bearing supports to, e.g., a base or adapter, they have eight holes on each side. This allows them to withstand any load, whether translational or rotational. Both bearing supports can be mounted to the required motor – linear lifting cylinder or three-phase motor – depending on the spatial direction to be measured, and can be screwed to necessary aids such as rails, rollers, an adapter or a rotatably mounted table.

On the drawing you can see an exemplary test rig. This shows how the printed bearing supports, developed by the students, can be used in a translational measurement with the linear stroke cylinder and in a rotational measurement with a three-phase motor.

We are happy that the Fab Lab can support students in their studies. So, if you also have a project in mind – whether as part of your studies or personal – just come by during our opening hours!

One of the first test prints for the interactive city model

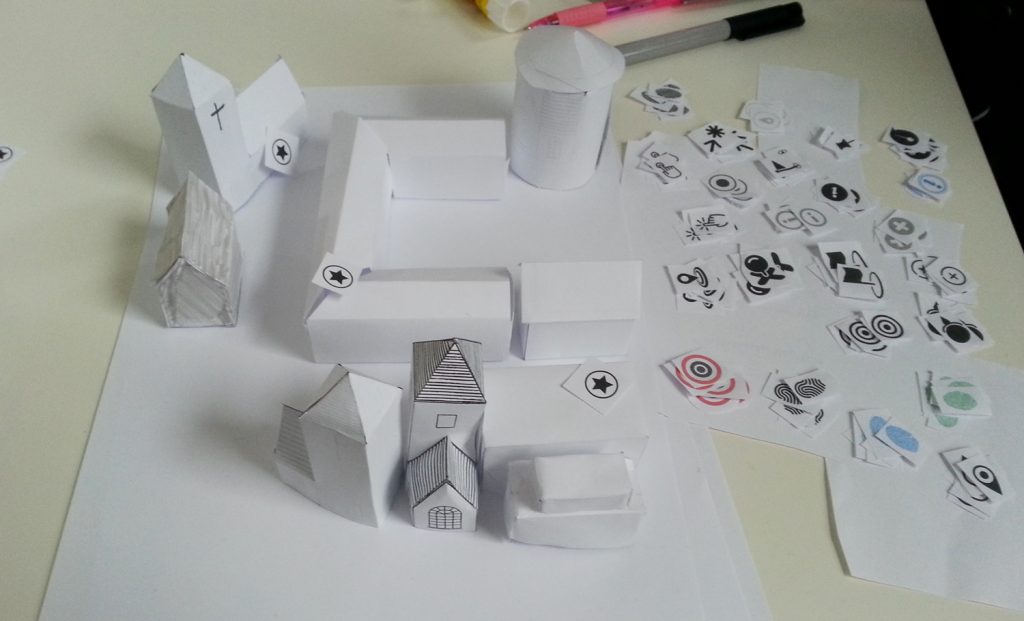

One of the first test prints for the interactive city model Paper prototype for the interaction concept of the city model

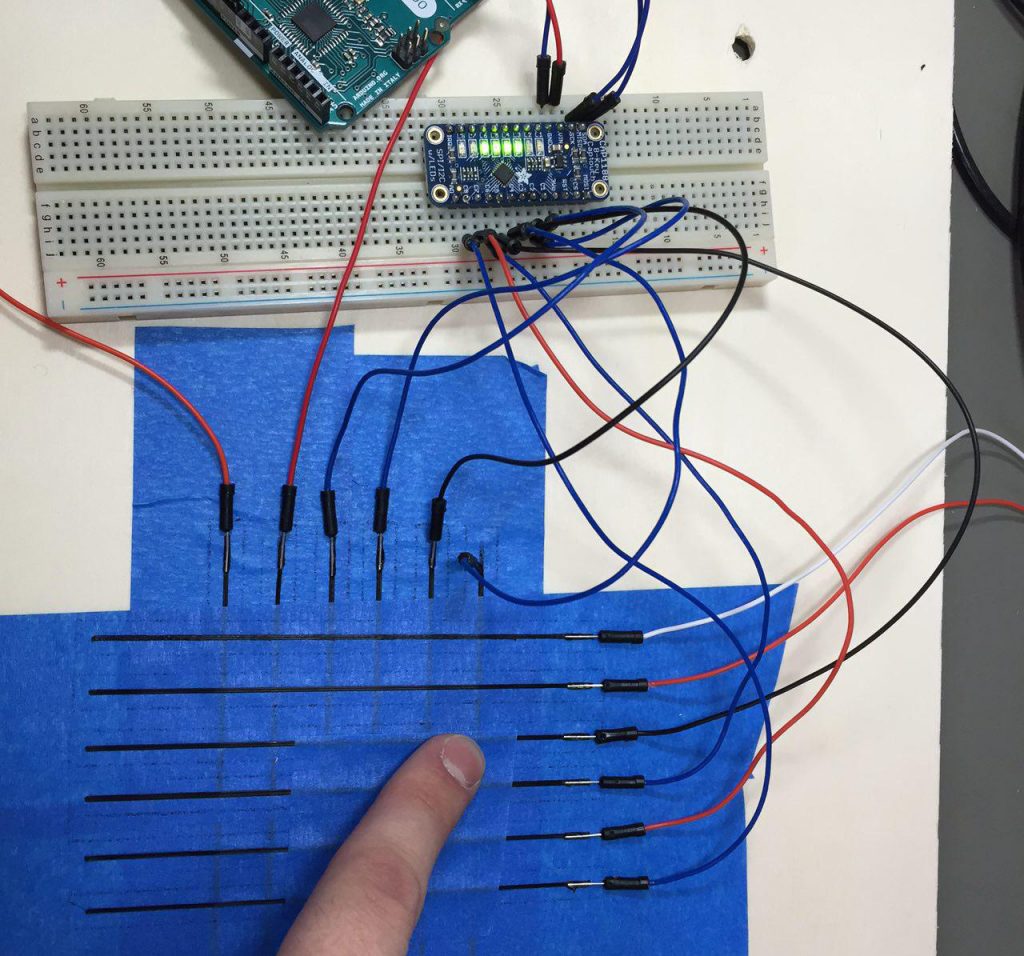

Paper prototype for the interaction concept of the city model Test of the sensor technology to be installed in the city model

Test of the sensor technology to be installed in the city model